Raws li cov khoom siv dav siv hauv cov yeeb nkab, cov yeeb nkab hlau yeeb nkab ua lub luag haujlwm tseem ceeb hauv ntau qhov chaw. Txawm li cas los xij, kev ntsuas ultrasonic suab nrawm muab kev lag luam-pom zoo thiab txhim khu kev qha los txheeb xyuas cov khoom ncaj ncees ntawm qhov chaw.

1. Cov yeeb nkab hlau thiab nws daim ntawv thov

DINSENductile hlau kavyog cov yeeb nkab uas ua los ntawm cov hlau nplaum los ntawm cov txheej txheem centrifugal casting. Nws muaj qhov zoo ntawm lub zog siab, siab toughness, corrosion resistance, high pressure resistance, thiab lwm yam, thiab yog dav siv nyob rau hauv lub nroog cov dej, kua, roj kis thiab lwm yam teb.

Hauv cov kav dej hauv nroog, cov kav dej xaim hlau tuaj yeem tiv taus cov dej siab kom ntseeg tau tias kev thauj mus los ntawm cov dej nyab xeeb. Nws zoo corrosion kuj tseem ua rau nws tsis tshua muaj kev cuam tshuam rau kev yaig los ntawm impurities hauv dej thaum siv mus sij hawm ntev, ncua kev pab cuam lub neej ntawm cov kav dej. Nyob rau hauv cov kav dej, lub zog siab thiab toughness ntawm cov kav dej hlau tuaj yeem tiv taus cov dej phwj tuaj thiab kev ua haujlwm ntawm sab nraud quab yuam kom ua haujlwm ruaj khov ntawm cov kav dej. Tsis tas li ntawd, cov kav hlau kav hlau kuj tseem ua lub luag haujlwm tseem ceeb hauv thaj chaw xws li kev xa cov pa roj. Lawv cov sealing zoo tuaj yeem tiv thaiv cov pa tawm thiab tiv thaiv tib neeg lub neej thiab khoom.

2. Cov txheej txheem thiab cov laj thawj rau kev kuaj xyuas cov spheroidization tus nqi ntawm cov kav hlau kav hlau

Cov txheej txheem kuaj xyuas

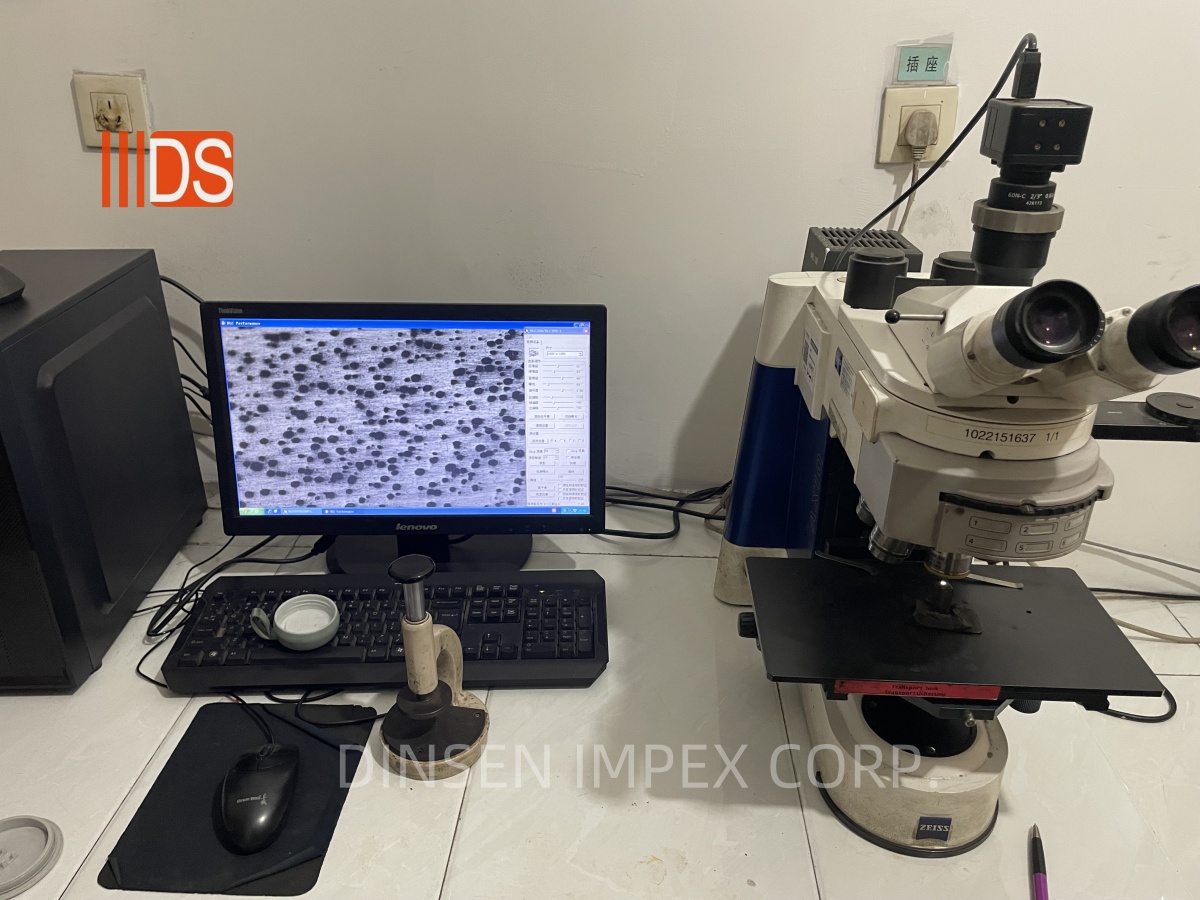

Metallographic tsom xam txoj kev: Qhov no yog ib qho kev siv feem ntau los kuaj xyuas tus nqi spheroidization. Los ntawm kev npaj cov qauv metallographic ntawm cov kav hlau hlau, cov morphology thiab kev faib tawm ntawm graphite raug soj ntsuam nyob rau hauv lub tshuab kuaj kab mob los txiav txim siab tus nqi spheroidization. Cov kauj ruam tshwj xeeb muaj xws li kuaj, inlaying, sib tsoo, polishing, corrosion thiab soj ntsuam. Txoj kev tsom xam metallographic tuaj yeem nkag siab qhov ntsuas spheroidization ntawm graphite, tab sis kev ua haujlwm yog qhov nyuaj thiab xav tau cov cuab yeej tshaj lij thiab cov kws tshaj lij.

Ultrasonic nrhiav txoj kev: Tus spheroidization tus nqi yog kuaj los ntawm kev siv cov yam ntxwv propagation ntawm ultrasonic tsis nyob rau hauv cov kav hlau kav. Kev nthuav tawm ceev thiab attenuation ntawm ultrasonic tsis nyob rau hauv cov hlau ductile nrog txawv spheroidization degrees yog txawv. Los ntawm kev ntsuas qhov tsis sib xws ntawm ultrasonic tsis, tus nqi spheroidization tuaj yeem ua tiav. Txoj kev no muaj qhov zoo ntawm kev ceev ceev, tsis muaj kev puas tsuaj thiab raug, tab sis nws yuav tsum muaj cov cuab yeej siv ultrasonic thiab software.

Thermal analysis method: Tus nqi spheroidization yog txiav txim siab los ntawm kev ntsuas cov thermal hloov ntawm cov kav hlau hlau thaum lub caij txias. Ductile hlau nrog zoo spheroidization yuav muaj cov thermal hloov nkhaus thaum lub caij txias. Los ntawm kev txheeb xyuas cov nkhaus no, tus nqi spheroidization tuaj yeem txiav txim siab. Kev ntsuas cua sov muaj qhov zoo ntawm kev ua haujlwm yooj yim thiab ceev ceev, tab sis nws qhov tseeb yog qhov tsawg.

Yog vim li cas rau kev sim

Xyuas kom cov khoom zoo: Spheroidization tus nqi yog ib qho tseem ceeb qhia ntawm cov hlau yeeb nkab zoo. Qhov siab dua tus nqi spheroidization, qhov zoo dua lub zog, toughness thiab corrosion kuj ntawm cov yeeb nkab. Los ntawm kev ntsuam xyuas tus nqi spheroidization, nws tuaj yeem ua kom ntseeg tau tias qhov zoo ntawm cov kav hlau hlau ua tau raws li tus qauv yuav tsum tau ua thiab muab cov neeg siv khoom txhim khu kev qha.

Txhim kho cov txheej txheem ntau lawm: Cov txiaj ntsig ntawm spheroidization tus nqi tuaj yeem muab rov qab rau cov tuam txhab los pab lawv txhim kho cov txheej txheem ntau lawm. Piv txwv li, yog tias tus nqi spheroidization qis qis, tus nqi ntawm spheroidizer ntxiv, casting kub thiab lwm yam tsis tuaj yeem hloov kho kom nce tus nqi spheroidization, yog li txhim kho cov khoom zoo.

Ua kom tau raws li cov neeg siv khoom xav tau: Hauv qee qhov tshwj xeeb, xws li kev xa hluav taws xob siab, qhov spheroidization tus nqi ntawm cov kav hlau kav yog siab heev. Los ntawm kev ntsuam xyuas tus nqi spheroidization, nws muaj peev xwm ua tau raws li cov kev xav tau tshwj xeeb ntawm cov neeg siv khoom thiab txhim kho kev lag luam kev sib tw ntawm cov khoom.

3. DINSEN lub chaw soj nstuam muab ductile hlau yeeb nkab spheroidization tus nqi kuaj rau cov neeg siv khoom Lavxias

Lub lim tiam dhau los, DINSEN lub chaw kuaj mob tau muab cov khoom siv hlau ductile spheroidization tus nqi ntsuas kev pabcuam rau cov neeg siv khoom Lavxias. Tom qab tau txais cov neeg tau txais kev pom zoo, peb sai sai txhim kho cov kws tshaj lij pab pawg thiab tsim cov phiaj xwm ntxaws ntxaws.

Ua ntej, peb siv kev sib xyaw ua ke ntawm metallographic tsom xam thiab kev kuaj ultrasonic los ua qhov kev ntsuam xyuas dav dav ntawm cov yeeb nkab hlau. Cov txiaj ntsig ntawm kev soj ntsuam metallographic tau pom tias cov graphite hauv cov yeeb nkab hlau muaj qhov zoo morphology thiab tus nqi siab spheroidization. Cov txiaj ntsig ntawm kev ntsuas ultrasonic kuj tseem ua tau raws li cov txiaj ntsig ntawm metallographic tsom xam, ntxiv txheeb xyuas qhov tseeb ntawm cov txiaj ntsig kev xeem.

Qhov thib ob, peb muab cov neeg siv khoom nrog cov lus qhia ntxaws ntxaws, suav nrog cov qauv kev xeem, cov txiaj ntsig kev xeem, cov lus xaus, thiab lwm yam. Tus neeg siv khoom txaus siab rau peb cov kev pabcuam kuaj thiab hais tias nws yuav koom tes nrog peb txuas ntxiv.

Los ntawm qhov kev sim no, peb tsis tsuas yog muab cov neeg siv khoom Lavxias nrog cov txiaj ntsig zoo, tab sis kuj tau txais kev nplua nuj nyob hauv spheroidization tus nqi ntsuas ntawm cov kav hlau kav. Peb yuav txuas ntxiv ua hauj lwm los muab cov neeg siv khoom nrog cov kev tshaj lij thiab kev kuaj xyuas kom zoo thiab pab txhawb rau kev tsim kho cov kav hlau yeeb nkab kev lag luam.

Nyob rau hauv luv luv, spheroidization tus nqi xeem ntawm cov kav hlau kav yog ib qho tseem ceeb txhais tau tias los xyuas kom meej cov khoom zoo, optimize ntau lawm txheej txheem, thiab raws li cov neeg xav tau kev pab.DINSENLaboratory yuav txuas ntxiv muab cov neeg siv khoom nrog cov kev kuaj xyuas kev tshaj lij thiab pab txhawb rau kev tsim kho cov kav hlau yeeb nkab kev lag luam.

Post lub sij hawm: Dec-17-2024